6" I.D. Standard Industrial Pitless Units-NSF 61 Certified

EXPLANATION OF PITLESS UNIT ORDERING NUMBERS

The diagram illustrates the meaning of the various letters and numerals used in Monitor Standard Industrial Pitless Unit ordering numbers. A typical order number and the pitless unit it stands for are shown.

- Installation Instructions

- Shipping Weights

- Spools And Cable Seals

- O-Ring Selection Guide

For CAD drawing contact sales at 800-356-5130 or e-mail monitorsales@baker-mfg.com.

- Features

- Specifications

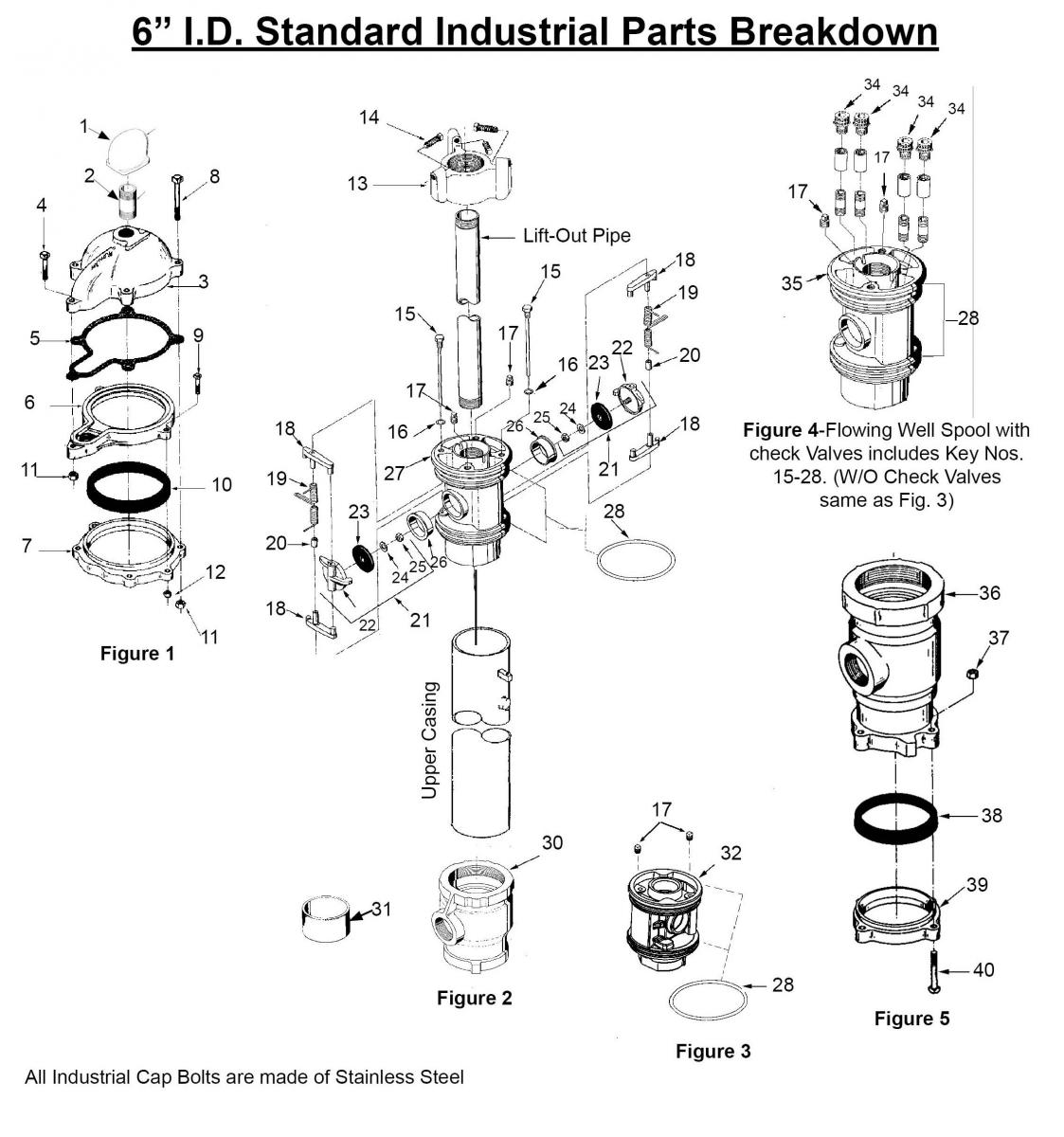

- Parts Breakdown

- Component Materials

- Ordering Instructions

CORROSION PROTECTION — all water passages are either hot-dipped lead free galvanized or constructed of corrosion resistant material

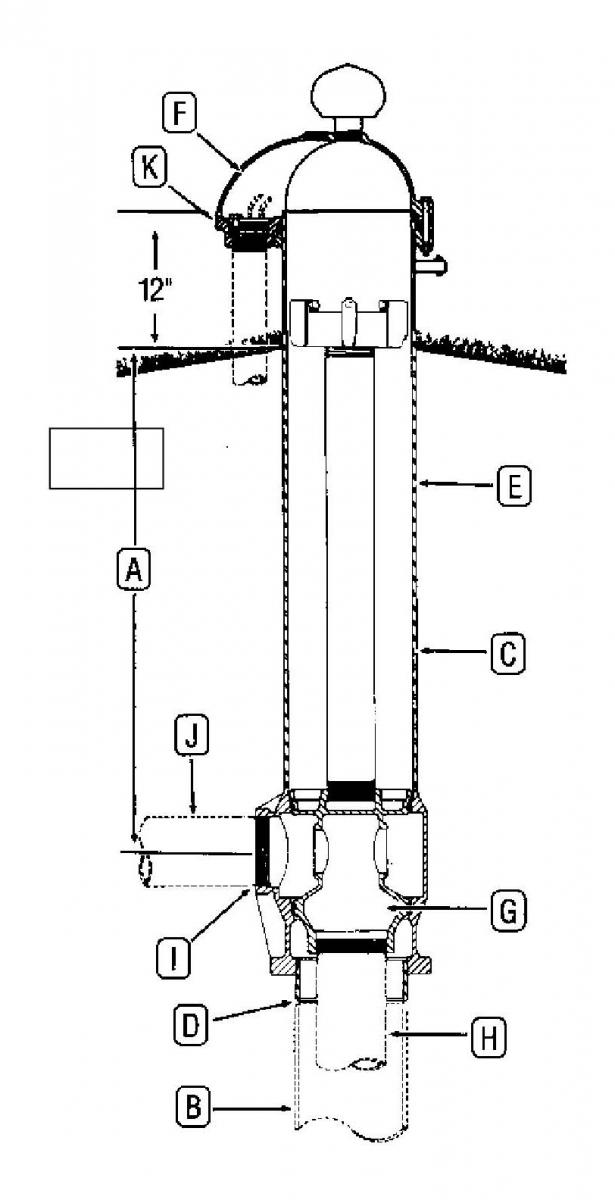

EASY TO SERVICE — Well cap can be removed without disconnecting cables. O-ring seals on spool permit withdrawal of the entire inner assembly simply by lifting. Replacement is equally simple. Spool support eliminates vertical adjustment and any possibility of dropping the inner assembly into the wall.

RELIABLE SEAL — Neoprene O-Rings between accurately machined hot-dipped lead free galvanized surfaces on the spool and within the unit provide positive seals.

O–RING SEAL PROTECTION — Monitor seal protection prevents seal damage during installation and service.

FROST PROOF — No Heating is required

QUICK TO INSTALL — A quality pump installation can be made easily and economically without delay for masonry or building construction

ALTERNATIVE SPOOLS — Spools are available plan (EO) or with silent check valves (E2-Double)

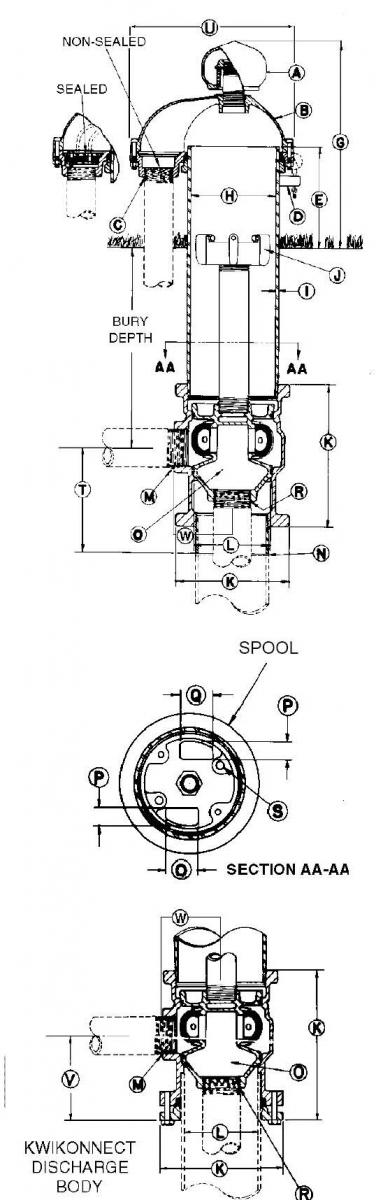

WATERTIGHT WELL CAP WITH SCREENED AIR VENT — Designed to permit removal without disconnecting cables. Watertight cable and conduit sealing is optional

HOLD-DOWN — Supplied with each unit. Hold-down pipe also serves as lift-out pipe for installation and servicing.

REINFORCED O-RING LANDS — Cast in to prevent discharge body from becoming out of round

DEPTH TEST BLOCK — Standard on all units

OPTIONS

SEALED CONDUIT CONNECTION — Watertight conduit seals made of neoprene are available for most common cable sizes. (Round Wire Only)

EPOXY PAINTING — Can be done, if required for extra protection in certain soil types

ADDITIONAL TAPPING IN SPOOL

TRANSITION SLEVE FOR MECHANICAL JOINT DISCHARGE

FLOWING WELL UNITS

Available in Stainless Steel upon request

|

|

Specifications are Subject to Change Without Notice.

For Flowing Well spool concept, see Booster Station section.

*Optional flange, weld or mechanical joint available upon request.

Note: Pitless units conform to the Recommended Standards for Water works, Great Lakes Upper Mississippi River Board of State Public Health & Environmental Managers and Water Systems Council PAS-97 (04) Standards.

COMPONENT MATERIALS

Well Vent - cast iron, green enamel finish.

Cap & Conduit Box - cast iron, green enamel finish.

Hold-Down Spider - cast iron, green enamel finish.

Hold-Down Pipe, 2” - steel Sch. 80, black.

Pitless Case - steel, black.

Spool - cast iron, lead-free galvanized.

Discharge Body - cast iron, lead-free galvanized.

Check Valve Body & Arms - brass.

Check Valve Seat - Brass.

Check Valve Spring - Monel.

Compression Seal Ring & Check Valve Facing - Neoprene.

Electrical Conduit Cable Seal - Neoprene.

Maximum Rated Discharge Pressure - 300PSI

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

EXPLANATION OF PITLESS UNIT The diagram illustrates the meaning of the various letters and numerals used in Monitor Custom Industrial Pitless Unit ordering numbers. A typical order number and the pitless unit it stands for are shown. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Typical Order Number 3PS67WBWE23T3S |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||